I have an item with a large stock variance, what's the cause?

Apicbase can help you with determining your stock variance. But what do you do when you know your stock variance? This article gives you some tips.

If you want to learn how to check for items with a large stock variance, read this article.

The article on how to check the stock variance starts with a checklist. This checklist checks everything you need in order to get your stock variance as low as possible. The first thing you have to do is double check if these items are as correct as you thought they were? The links to the articles on these items are added tot the list. Just click the hyperlinks.

- Is all my ingredient and package/supplier information correct in Apicbase?

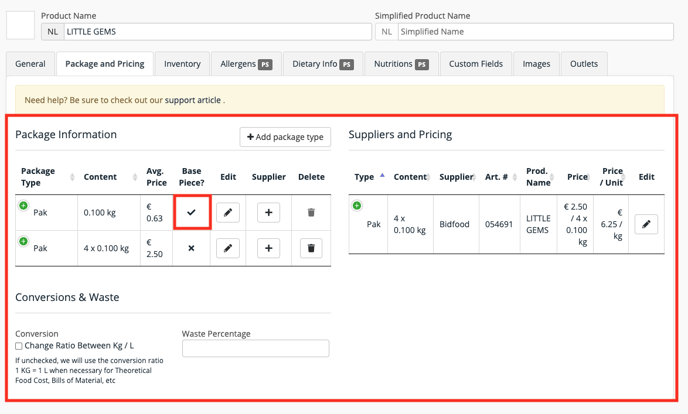

- If you have an item with a large variance. Check if the ingredient and package/pricing information is correct. You can find this info in the ingredient info in the "Package and pricing" tab.

- Is the package quantity and unit defined correctly?

- If you have set a piece, is this for the right package (check in edit mode)?

- e.g. If you have an ingredient apples and the package is 1kg and this package is set as a piece, it can happen that this ingredient is added to recipes as a piece by mistake. According to Apicbase 1kg will be taken out of stock if a piece is used.

- e.g. in the example above one pack of 100g of gem lettuce is defined as a piece.

- If you have an item with a large variance. Check if the ingredient and package/pricing information is correct. You can find this info in the ingredient info in the "Package and pricing" tab.

- Are my recipes correctly inputted in Apicbase?

- Are all the ingredients correctly assigned to the recipes?

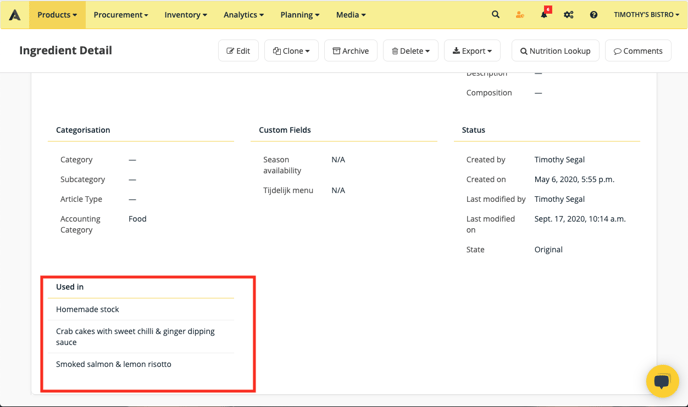

- First go to the ingredient that has the big variation and open the ingredient ("Products">"Ingredients") in edit mode

- Scroll down and there you see in which recipes the ingredient is used.

- When you click (tip: when you do a ctrl+click the new page opens in a new tab, this is handy when you have to check a lot of recipes) on each recipe, the recipe opens and here you can check if:

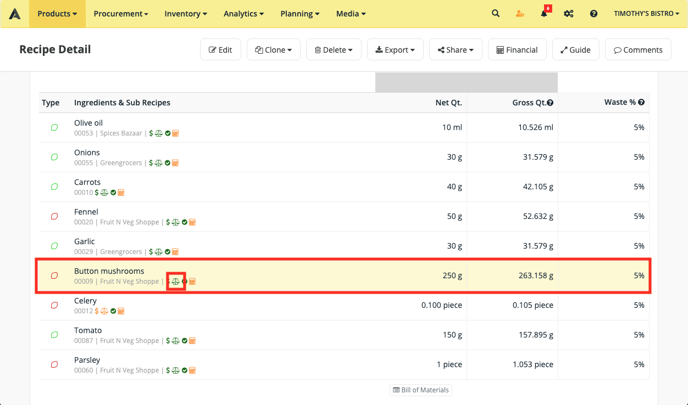

- The ingredient is added to the recipe, it is linked to an ingredient in the database with the package and pricing information (the scale symbol next to the ingredient is green in this case).

- The right amount is added to the recipe.

- Repeat this for all the recipes the ingredient is linked too.

- Is the waste correctly filled in?

- In the recipe detail you can check the waste that is set for this ingredient. This can be set on recipe or library level.

- Are all the ingredients correctly assigned to the recipes?

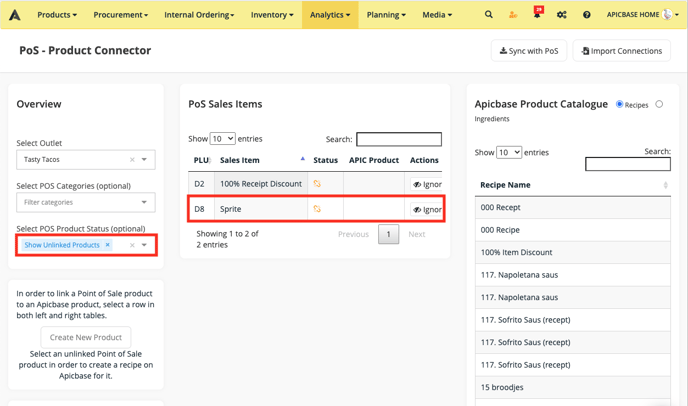

- Are the recipes linked to the POS-items?

- In your sales analytics module, you can filter on unlinked items. These are all the items in you POS that are not linked to an Apicbase product or recipe. Some PLU's don't have to be linked, like for example reduction PLU's. If PLU's that do need linking are not linked, the ingredients of this recipe will not be taken out of stock correctly.

In this example the sprite PLU is not linked to an Apicbase recipe.

In this example the sprite PLU is not linked to an Apicbase recipe.

- In your sales analytics module, you can filter on unlinked items. These are all the items in you POS that are not linked to an Apicbase product or recipe. Some PLU's don't have to be linked, like for example reduction PLU's. If PLU's that do need linking are not linked, the ingredients of this recipe will not be taken out of stock correctly.

- Are all the orders registered in Apicbase?

- Are the orders sent in Apicbase?

- Are the orders received in Apicbase?

- External orders?

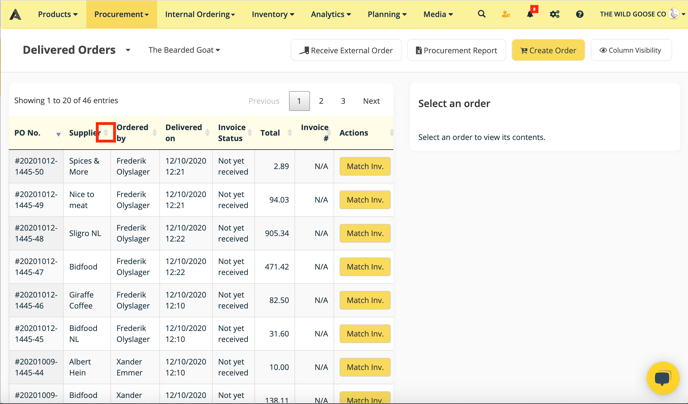

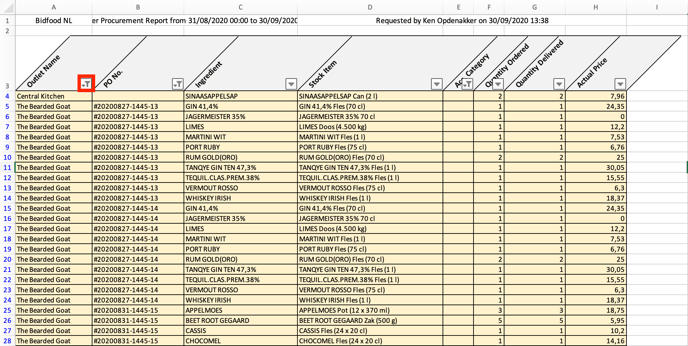

you can check if orders were received in the procurement module by clicking the "Delivered orders". Here you can check all the delivered orders in Apicbase. You can filter on supplier to have an overview of all the orders per supplier. You can also check the supplier procurement report. Here you have an overview of all the orders between the selected period. You can filter in the column headers from the excel file on Outlet and you also have the PO number generated by Apicbase.

You can also check the supplier procurement report. Here you have an overview of all the orders between the selected period. You can filter in the column headers from the excel file on Outlet and you also have the PO number generated by Apicbase.

- Is all the waste registered correctly by my staff?

This can be checked in the waste module or by generating a waste report. - Are all the transfers registered regularly?

You can check this by opening the transfer module and checking all the transfer events. - Are all the stockable recipes "created" in stock on a regular basis?

As with the two last, you can check this by opening the "Create" module. - If non of these checks give an insight into why the theoretical stock is not correct, you will have to check elsewhere. Other reasons for incorrect stock could be:

- Items were stolen out of stock.

- There was over-portioning in the kitchen.