What is PAR and how to use it?

PAR levels help ensure your stock levels remain optimal, avoiding both shortages and excess inventory.

Table of content

1.3. Bulk Updates Through Excel

2.1. Ordering for One Ingredient

3. Taking Outstanding Orders into Account

4. Ensuring Accurate Inventory Management

PAR (Periodic Automatic Replenishment) is a system that helps businesses maintain a target stock level for each ingredient. The PAR level is the ideal amount of stock that should be kept on hand at all times. When inventory falls below the set PAR level, this system prevents shortages and overstocking, ensuring a consistent supply of essential ingredients.

PAR levels can vary between locations, as each outlet might have different sales volumes or usage patterns for the same item. For example, a busy downtown café might sell 100 loaves of bread per day, while a more quiet suburban café might only sell 30 loaves per day. As a result, the downtown café would set a higher PAR level for bread say, 150 loaves, while the suburban café may only need a PAR level of 50 loaves.

By adjusting PAR levels for each location or even for each season (when summers are more busy than winters), you can ensure that each outlet is properly stocked according to its specific needs, avoiding both stockouts and overstocking, and keeping your business running smoothly.

1. Setting up PAR Levels

There are multiple ways to set up and manage PAR levels for ingredients in Apicbase. PAR levels need to be set per ingredient and per outlet, allowing businesses to customize stock levels based on the specific needs of each location. Whether you need to update individual items or make bulk changes, the platform provides flexible options to suit your business needs.

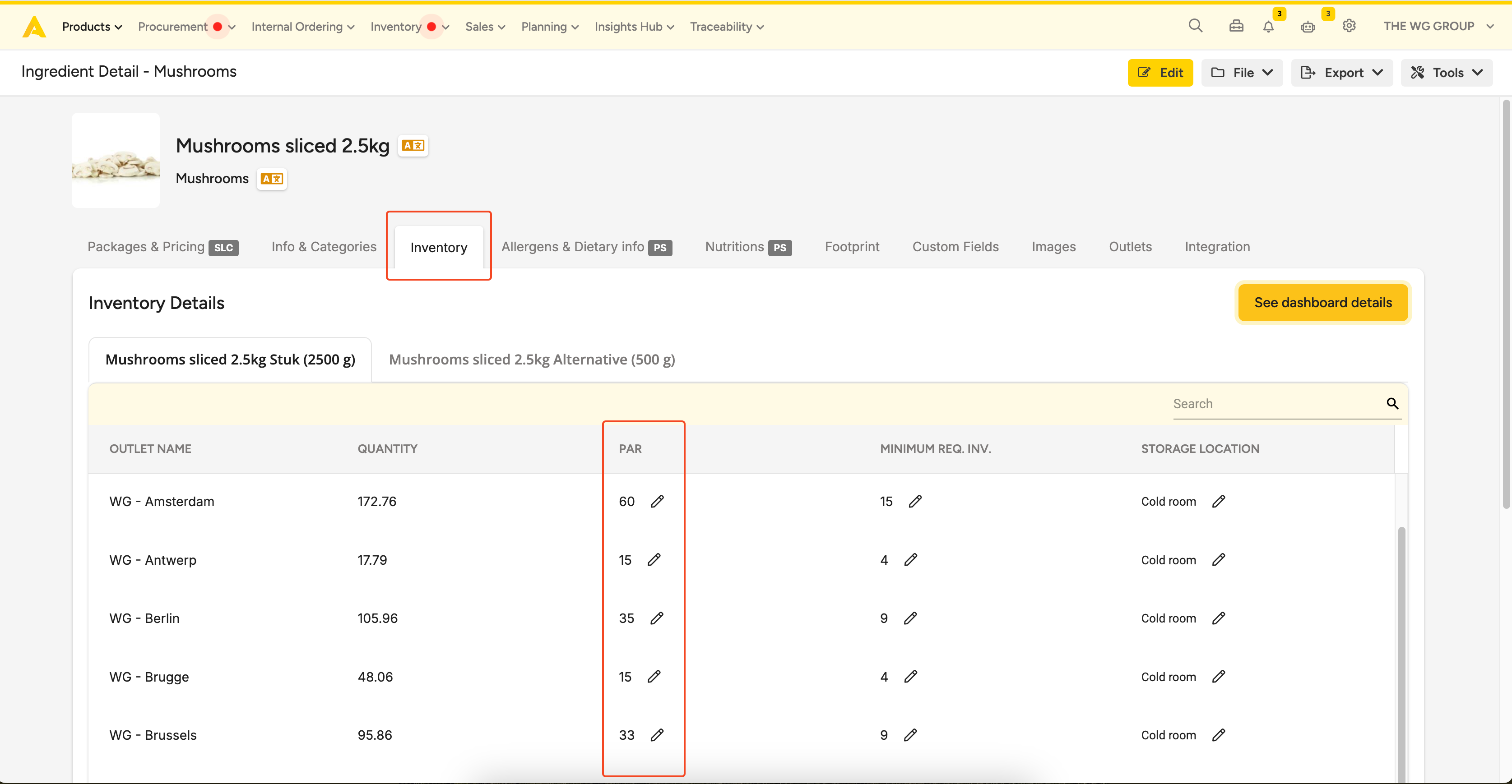

1.1. Manually per Ingredient

- Access the ingredient details.

- In the inventory section, click the pen icon to specify the desired PAR level for each ingredient, for each outlet.

- You can edit the PAR level even without going into edit mode. The system will automatically save the edits as soon as you update the values, making it quicker and easier to manage your inventory.

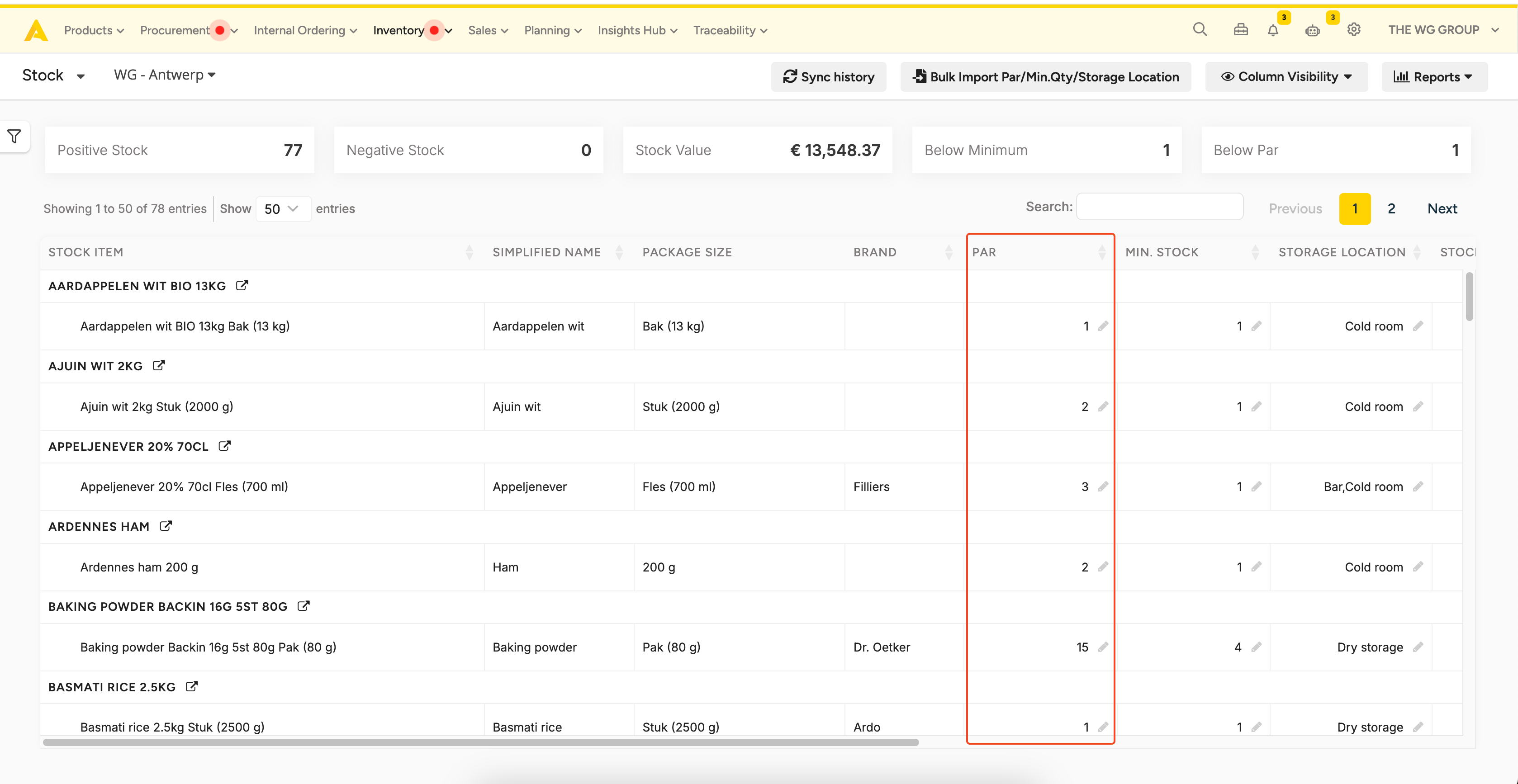

1.2. Manually per Outlet

- Go to Inventory > Stock > Choose an outlet.

- Click the pen icon to edit the PAR level for each product.

- The system automatically saves your changes as soon as you update the PAR level.

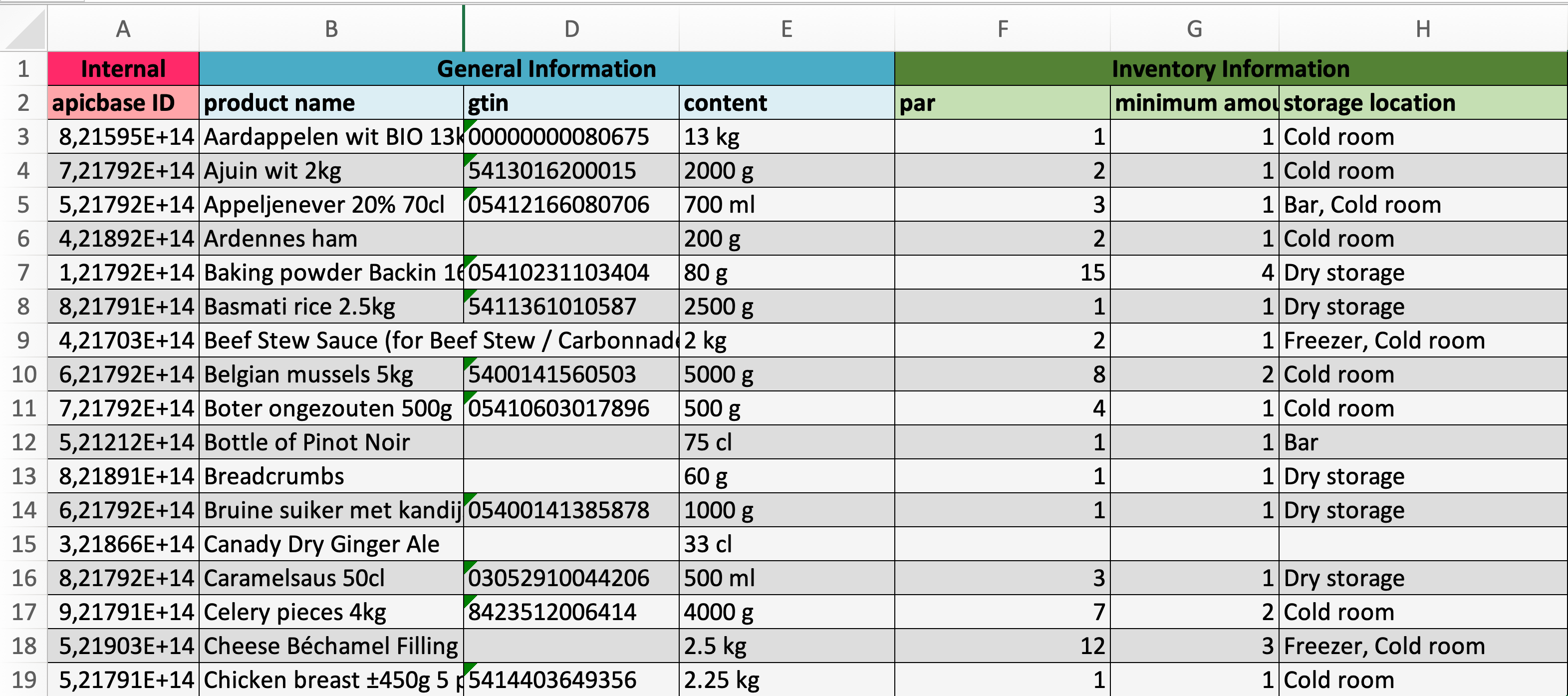

1.3. Bulk Updates Through Excel

- Go to Inventory > Stock > Choose an outlet.

- Click Bulk Import Par/Min. Qty/Storage Location.

- You will be redirected to a page where you can (1) download your latest stock item list. Alternatively, you can also access this same page by going to: Settings > Outlet Settings > Edit Outlet Settings > Inventory.

- In the excel file, fill out the PAR column with the desired values for each ingredient.

- Once the file is updated, (2) upload the Excel file back into Apicbase.

2. Ordering to PAR

Once the system has calculated the required quantities for each ingredient, users can add the ingredients that need replenishing to their shopping basket in a single action, ensuring a streamlined and efficient ordering process.

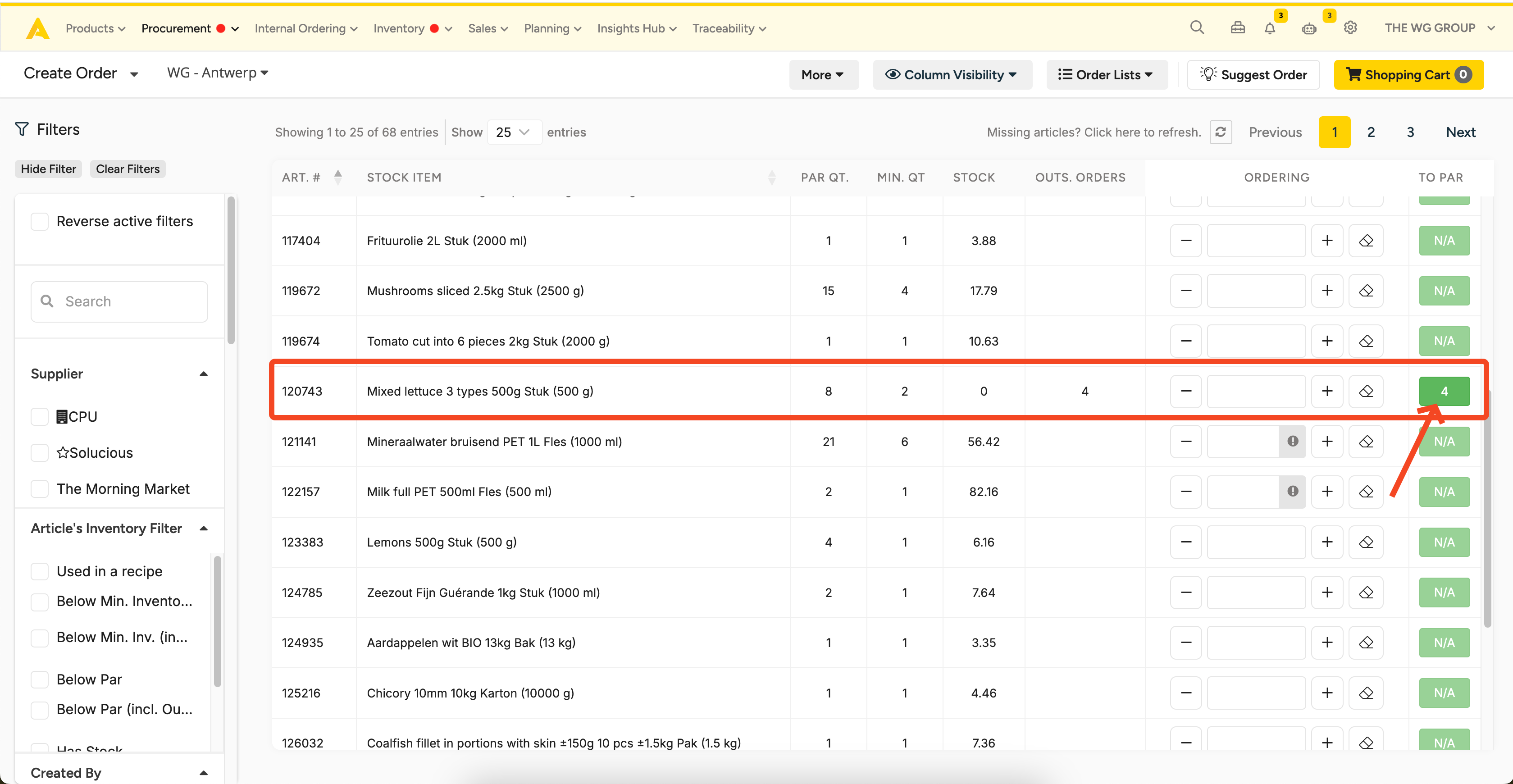

2.1. Ordering for One Ingredient

- Navigate to the Create Order view.

- Click on the (1) green button next to the ingredient you want to order. The number that appears in the green button is automatically placed in the quantity box.

This number represents the quantity required to bring the ingredient's stock level up to the PAR level. To calculate the top-up amount, Apicbase takes into account two factors:

- Current stock: The amount of the ingredient you currently have in your inventory.

- Outstanding orders: Any orders that have already been placed but not yet received. (s: add that this will be taken into account when PAR is calculated)

In other words, the top-up amount (the 'To PAR') is calculated as:

Top-up = PAR Quantity - Current Stock -Outstanding Orders

2.2. Order All to PAR

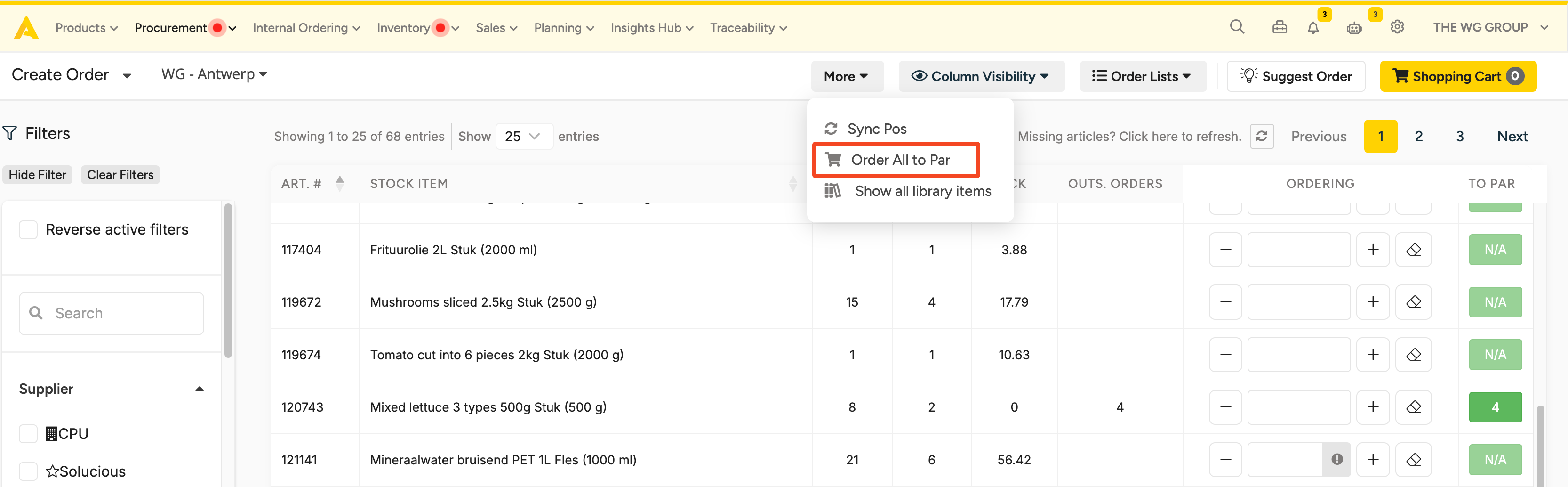

The ordering process can be simplified by allowing users to reorder multiple ingredients at once using the 'Order All to PAR' feature. To do this:

- Go to Procurement > Create Order.

- Click More.

- Select Order All to PAR.

- Apicbase will automatically add all ingredients that need replenishing to the order. In case filters are applied, Apicbase will only insert the top-up amounts for products in the filtered view.

- A pop-up message will appear displaying how many PAR levels, orders, and suppliers are being processed in the order.

- Once the order is ready, click Send Order to complete the process.

3. Taking Outstanding Orders into Account

An important aspect of the PAR is its ability to factor in outstanding orders. This means that when a business has already placed an order for ingredients that have not yet been received, the system will account for this when calculating how much stock needs to be ordered. By considering outstanding orders, Apicbase ensures that businesses do not over-order or under-order based on both current stock and incoming deliveries.

-

Outstanding Orders column

The "Outstanding Orders" (OUTS. ORDERS) column, visible in both the Order and Stock pages, represents the number of pending or unfulfilled orders for each item. It helps you track which items still need to be processed or delivered, providing insight into demand and allowing for better inventory planning.

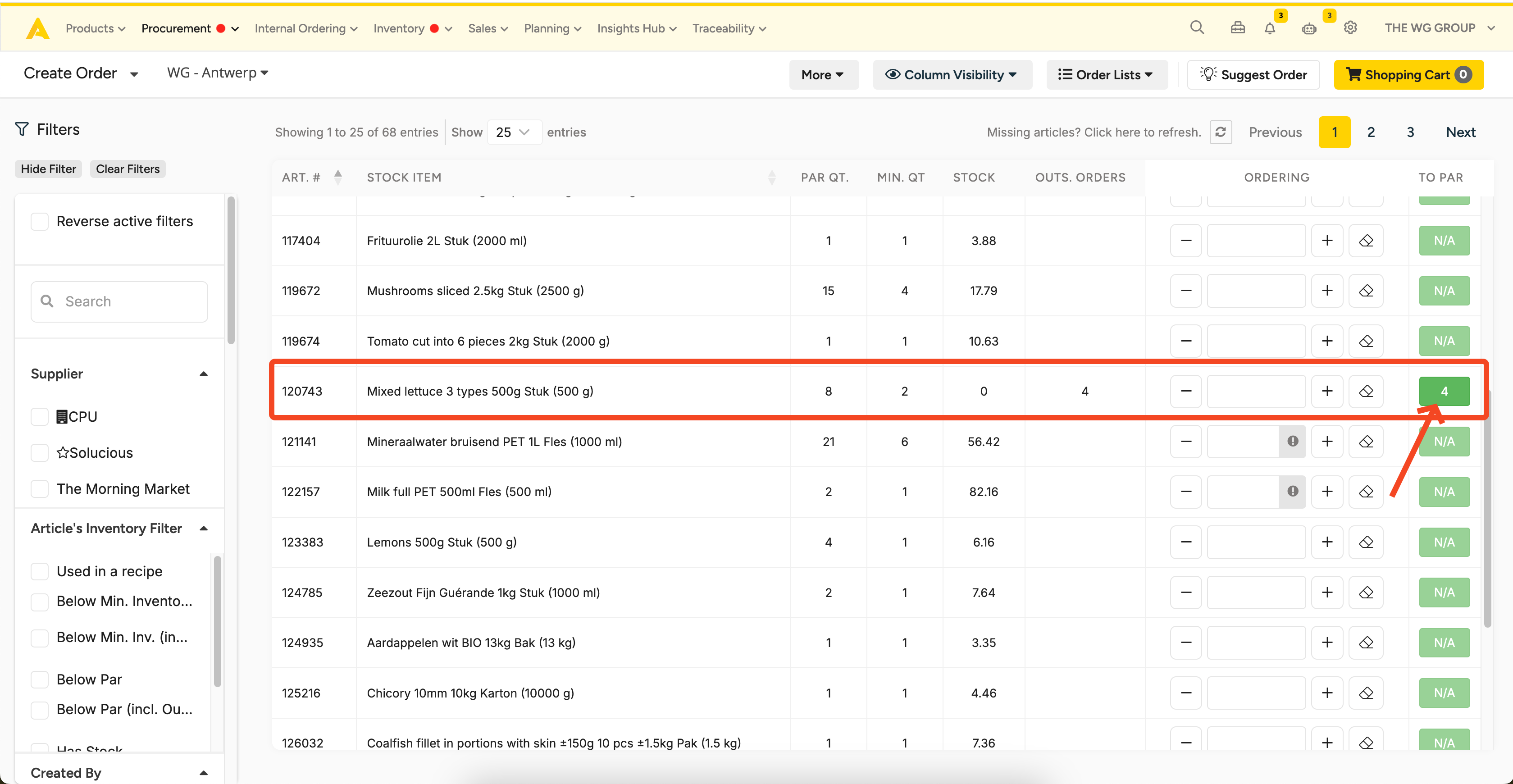

For instance, in the photo below, there is a stock item labeled (1) Mixed lettuce with a (2) PAR level of 8, and there are currently (3) zero in stock. Apicbase recognizes the (4) outstanding order quantity, which is 4, and only suggest an order for the (5) remaining 4 to reach the PAR level.

This dynamic approach ensures that your inventory stays balanced, ordering just what is needed to meet demand, preventing both overstocking and stockouts.

💡You can use the Below PAR (incl. Outstanding Orders) filter to see ingredients that have fallen below their designated PAR level, even after factoring in outstanding orders. This ensures you know which items need replenishment, even if a previous order is still in transit.

This filter appears in the Article's Inventory Filter and can be found in the Ordering page, Stock page, and Counting page, making it easy to keep track of stock levels across all stages of your inventory management. It's a useful tool to ensure you never miss an item that needs reordering.

4. Ensuring Accurate Inventory Management

It’s crucial to close orders to ensure that there are no discrepancies in the outstanding orders and PAR levels. Unclosed orders can create confusion by continuing to show as "in transit," even if the items have already been delivered. However, it’s not just about closing orders, keeping your inventory as up to date as possible is essential. This includes registering your sales, waste, counts, and any other stock movements. Accurate inventory data is critical because when you're using PAR to place orders, you're ordering based on your stock levels. If those stock levels are incorrect, your orders will be flawed, resulting in over-ordering or under-ordering.

Additionally, there’s a PoS sync button next to the Order All to PAR feature, which helps you keep your stock data current. This button is only visible for outlets that have a PoS system connected. By clicking this button, you can trigger an immediate sync with your PoS system, ensuring that you have the latest stock updates before placing your order. While Apicbase syncs with the PoS every morning by default, manually syncing in the middle of the day can provide a more accurate picture of your stock. The sync process may take a few minutes, so it’s a good idea to trigger it in advance to ensure your data is up to date.

By updating your stock, closing orders promptly, and using the PoS sync feature, you ensure that the PAR system works with the most accurate information, leading to more efficient inventory management and better ordering decisions.